Mechanical Condensate Recovery System

Mechanical Condensate Recovery System Specification

- Control System

- Float / Mechanical Lever

- Voltage

- 220-240 V AC

- Features

- No external power required, Compact Design, Easy Maintenance

- Speed

- 2900 RPM

- Discharge Pressure

- Up to 10 bar

- Working Temperature

- Up to 180C

- Frequency

- 50 Hz

- Theory

- Mechanical Condensate Recovery

- Noise Level

- Less than 75 dB

- Head Size

- 15-20 m

- Caliber

- DN25

- Max Suction

- 6-8 meters

- Mounting Type

- Skid Base Mounted

- Flow Rate

- 2-10 m/h

- Inlet/Outlet

- DN25 / DN40

- Material

- Mild Steel / Stainless Steel

- Structure

- Horizontal Mounted

- Power

- 1.5 kW

- Standard

- IS: 8479 / ASME standards

- Fuel Type

- Electric

- Pressure

- 6-10 bar

- Usage

- Condensate/Waste Heat Recovery

- Application

- Industrial Steam Systems

- Suction Type

- Direct Suction

- Seals Type

- Mechanical Seal

- Priming

- Automatic

- Pump Type

- Mechanical Pump

- Capacity

- 100-150 liters per cycle

- Weight

- 120-150 kg

- Internal Components

- Stainless Steel

- Condensate Return Line Size

- DN25 to DN40

- Max Inlet Pressure

- 16 bar

- Body Finish

- Anti-Corrosive Paint

- Protection Class

- IP55

- Connectivity

- Manual/Automated Options

- Maintenance Interval

- 1500 Operating Hours

- Installation

- Indoor/Outdoor

- Service Life

- >10 Years

Mechanical Condensate Recovery System Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

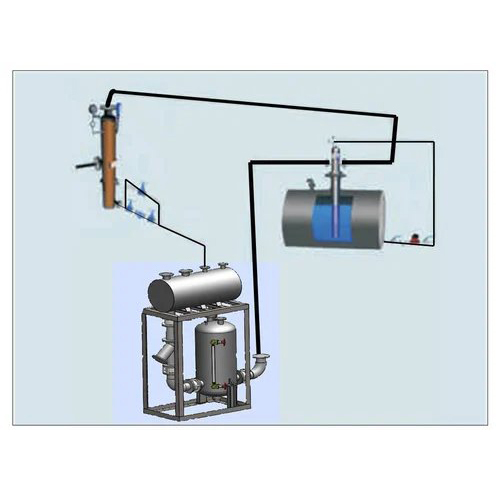

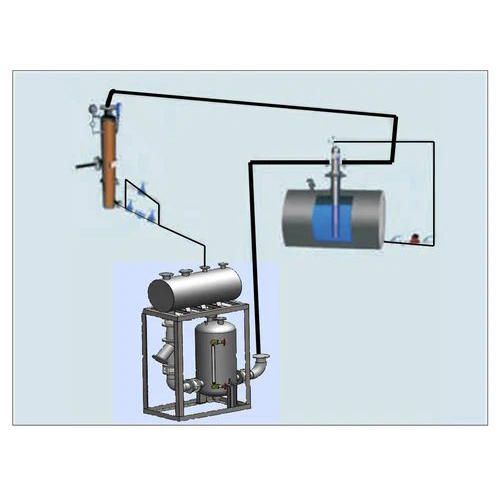

About Mechanical Condensate Recovery System

Application and Area of Use

The Mechanical Condensate Recovery System is specifically designed for general and specialized industrial steam systems, serving clients in power plants, manufacturing units, and large facilities. Used extensively by engineers and maintenance teams in both indoor and outdoor settings, it efficiently recovers waste heat and condensate, reducing operational costs and supporting sustainable practices on-site.

Packaging, Export Markets, and Certifications

Expenditure on packaging ensures robust protection during shipping, guaranteeing the system arrives intact and ready for installation. Shipped globally, with quotations available for international and domestic clients, IEPL focuses on key export markets in Asia, Europe, and the Middle East. Certified to IS:8479 and ASME standards, each system assures safety, reliability, and compliance for every shipment.

Specification

|

Brand |

IEPL |

|

Material |

Mild Steel |

|

Phase |

No requirement Pure mechanical |

|

Model Name/Number |

Mechanical Condensate Recovery Pump |

|

Country of Origin |

Made in India |

|

Colour |

Tata Blue |

|

Air/ Steam Flow |

3-3.5 kg |

FAQ's of Mechanical Condensate Recovery System:

Q: How does the Mechanical Condensate Recovery System improve steam system efficiency?

A: This system recovers and reuses condensate and waste heat from industrial steam applications, minimizing water and energy losses, and lowering overall operational costs.Q: What are the specific installation requirements for the condensate recovery system?

A: The system can be installed indoors or outdoors, includes a skid base mount, and operates with either manual or automated connectivity. No external power is required due to its advanced mechanical design.Q: When should the system be serviced to maintain optimal performance?

A: Routine maintenance is recommended every 1500 operating hours to ensure longevity and consistent performance throughout its service life of over 10 years.Q: Where is this system commonly utilized?

A: It's widely used in industrial settings such as power plants, food processing facilities, textile mills, and any site where steam condensate recovery is essential.Q: What is the main benefit of using this condensate recovery system?

A: The main benefit is substantial energy and cost savings achieved by maximizing recovery of steam condensate and waste heat, supported by robust construction and long-term reliability.Q: How does the automatic priming and direct suction feature work in practice?

A: Automatic priming prepares the system for immediate operation, while direct suction efficiently draws condensate, enabling swift collection and return in various operational scenarios.

Price 120000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Condensate Recovery System Category

Condensate Recovery Unit

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Other, Condensate recovery in steam systems

Frequency : 50/60 Hz

Structure : Other, Horizontal/Vertical

Speed : 2800 RPM

High Condensate System for Steam

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Other, Steam Condensate Recovery

Frequency : 50/60 Hz

Structure : Other, Compact Skid Mounted

Speed : 2900 rpm

Boiler Condensate Pump

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Other, Boiler System Condensate Transfer

Frequency : 50 Hz / 60 Hz

Structure : Other, Horizontal

Speed : 2900 rpm

Condensate Flash Recovery System

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Other, Condensate Recovery

Frequency : 50 Hz / 60 Hz

Structure : Other, Horizontal Multistage

Speed : 2900 rpm