Condensate Flash Recovery System

Condensate Flash Recovery System Specification

- Inlet/Outlet

- Flanged Ends

- Frequency

- 50 Hz / 60 Hz

- Control System

- Automatic Level Controller

- Working Temperature

- Up to 180C

- Mounting Type

- Skid Mounted

- Noise Level

- <70 dB(A)

- Theory

- Centrifugal Pump

- Features

- Energy Efficient, Compact Design, Low Maintenance

- Head Size

- Up to 60 m

- Flow Rate

- 1 to 50 m/hr

- Speed

- 2900 rpm

- Discharge Pressure

- Up to 10 Bar

- Voltage

- 415 V

- Max Suction

- Up to 7 m

- Caliber

- DN25 to DN100

- Material

- Stainless Steel 304/316

- Structure

- Horizontal Multi-stage

- Power

- 1 HP to 15 HP

- Standard

- ASME / IS Standards

- Fuel Type

- Electric

- Pressure

- Up to 10 Bar

- Usage

- Condensate Recovery

- Application

- Industrial Steam, Boiler Houses

- Suction Type

- Flooded Suction

- Seals Type

- Mechanical Seal

- Priming

- Self Priming (optional)

- Pump Type

- Condensate Pump

- Capacity

- Customizable

- Ambient Temperature

- Up to 50°C

- System Type

- Automatic/Manual Operation

- Cleaning

- Easy Maintenance Access

- Surface Finish

- Mirror/Mat Polish

- Display Option

- Digital/Analog Level Indicator

- Tank Material

- SS 304/316

- Protection Class

- IP55

- Drain Connection

- Available

- Insulation

- Thermal Insulation Provided

- Pump Body

- Robust Construction for Industrial Usage

- Service

- After-Sales and Installation Support

Condensate Flash Recovery System Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Condensate Flash Recovery System

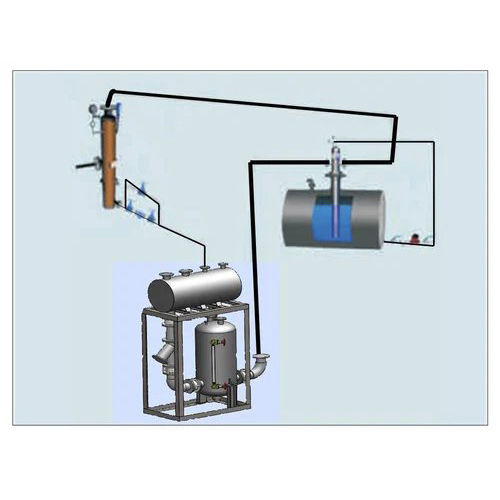

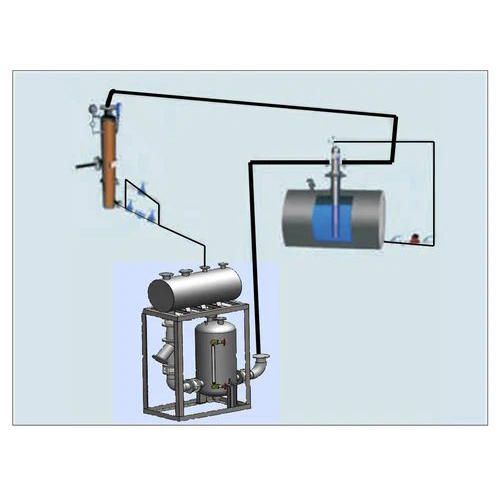

Introducing our Condensate Flash Recovery System, a revolutionary solution for optimizing energy efficiency in steam processes. This system efficiently captures and recovers flash steam from high-pressure condensate, converting it into valuable energy. Engineered for reliability and durability, it seamlessly integrates into existing setups, reducing heat loss and enhancing overall system performance. The user-friendly design ensures straightforward installation and operation. By maximizing the recovery of flash steam, this system not only lowers operational costs but also aligns with sustainable practices, contributing to reduced environmental impact. Upgrade your steam processes with our Condensate Flash Recovery System an advanced, cost-effective, and eco-conscious solution for energy recovery.

Specification

|

Material |

M.S, S.S |

|

Model Name/Number |

CONDENSATE PUMP |

|

Brand |

Innovative Enerpro Pvt Ltd. |

|

Model Number |

P1M /P2M/ ... /P11M/P12M |

|

Size |

1 to 12 TPH |

|

Country of Origin |

Made in India |

Superior Thermal Protection and Industrial Durability

With thermal insulation provided and a robust SS 304/316 tank construction, the Condensate Flash Recovery System is engineered to withstand harsh industrial conditions and high working temperatures. This ensures enhanced equipment longevity while maintaining superior energy efficiency by minimizing heat loss.

User-Friendly Maintenance and Control

The system is designed with easy maintenance access, allowing quick cleaning and servicing. An automatic level controller, digital/analog display options, and both manual and automatic operations streamline user interaction, keeping operations smooth and efficient for industrial steam and boiler houses.

Comprehensive Support and Customization Options

Our offering includes full after-sales and installation support for hassle-free integration into your facility. The system supports a wide range of capacities and configurations, including customizable flow rates, head sizes, and mounting types. Compliance with ASME/IS standards ensures reliable performance and safety.

FAQ's of Condensate Flash Recovery System:

Q: How does the Condensate Flash Recovery System enhance energy efficiency in industrial settings?

A: The system's advanced thermal insulation and centrifugal pump technology minimize heat loss during condensate recovery, optimizing steam usage and reducing energy consumption for industrial boiler and steam applications.Q: What type of maintenance is required for the Condensate Flash Recovery System?

A: Routine maintenance involves easy access for cleaning, inspection of mechanical seals, and periodic checks of the pump body and level indicators. The system is engineered for low-maintenance operation and quick servicing.Q: Where can this system be installed, and what environments is it suitable for?

A: It is designed for industrial steam and boiler houses, suitable for ambient temperatures up to 50C and working temperatures up to 180C. The robust construction and IP55 protection class ensure reliability in demanding industrial environments.Q: When should condensate be recovered using this system?

A: Condensate should be recovered continuously during industrial steam and boiler operations to improve efficiency, reduce water and energy usage, and minimize operational costs. The system supports both automatic and manual operation for flexible integration.Q: What are the key benefits of the automatic/manual operation and control system?

A: Automatic/manual operation provides operational flexibility, while features such as digital/analog level indicators and automatic level controllers offer precise monitoring and control for safe and efficient condensate management.Q: How is the system customized to match different application requirements?

A: The system accommodates customizable head sizes, flow rates, tank capacities, and mounting options. It supports DN25 to DN100 caliber with flanged ends, making it suitable for various industrial setups and process demands.

Price 160000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Condensate Recovery System Category

Condensate Recovery System

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Standard : IS/ISO certified

Seals Type : Mechanical Seal

Power : Other, 0.752.2 kW

Inlet/Outlet : 25 mm / 25 mm (BSP Threaded)

Condensate Return Unit

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Standard : ISO 9001:2015

Seals Type : Mechanical Seal

Power : Other, 0.55 HP

Inlet/Outlet : 1 to 2 BSP/NPT

Boiler Condensate Pump

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Standard : ISI / ISO

Seals Type : Mechanical Seal

Power : Other, 0.754 kW

Inlet/Outlet : 25 mm / 25 mm

Mechanical Condensate Recovery Pump With Panel

Price 140000 INR / Unit

Minimum Order Quantity : 1 Unit

Standard : ISI/ISO Approved

Seals Type : Mechanical Seal

Power : Other, 0.5 HP to 2 HP

Inlet/Outlet : 1 BSP / 1 BSP