Condensate Recovery Unit

Condensate Recovery Unit Specification

- Noise Level

- Low (<70 dB)

- Frequency

- 50/60 Hz

- Caliber

- Standard/Custom sizes

- Speed

- 2800 RPM

- Flow Rate

- 0.5 m/hr to 20 m/hr

- Head Size

- 10 to 45 meters

- Inlet/Outlet

- As per requirement (commonly 1 to 4)

- Max Suction

- 6-8 meters

- Control System

- Automatic/Manual

- Theory

- Centrifugal Pump

- Mounting Type

- Base Mounted/Skid Mounted

- Discharge Pressure

- Up to 6 kg/cm

- Voltage

- 220/380V

- Features

- Corrosion-resistant, Energy Efficient, Easy Installation

- Working Temperature

- 0C to 120C

- Fuel Tank Capacity

- N/A (Electric powered)

- Material

- Mild Steel/SS304/SS316

- Structure

- Horizontal/Vertical

- Power

- 0.5 HP to 15 HP

- Standard

- IS/ISO standards

- Fuel Type

- Electric

- Pressure

- Up to 6 kg/cm

- Usage

- Condensate recovery in steam systems

- Application

- Boiler Feed, Steam System Automation

- Suction Type

- Direct/Indirect

- Seals Type

- Mechanical Seal

- Priming

- Self/Manual (as selected)

- Pump Type

- Single/Multistage Centrifugal

- Capacity

- As per requirement (customized)

Condensate Recovery Unit Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Condensate Recovery Unit

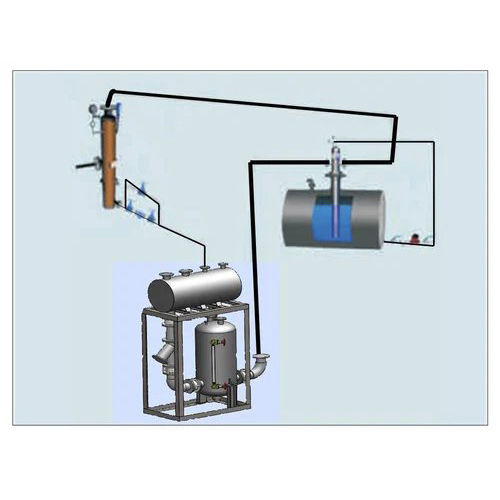

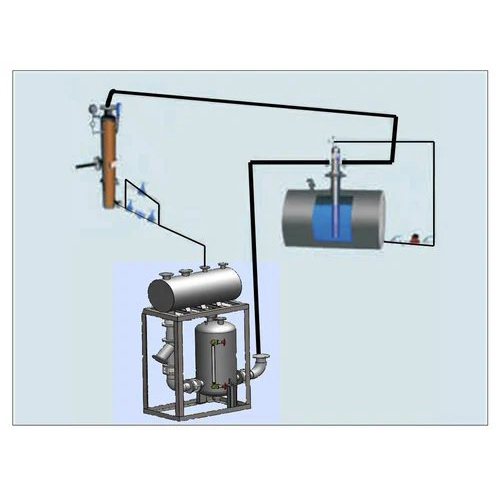

Introducing our Condensate Recovery Unit, a pinnacle of efficiency in steam system management. This comprehensive solution seamlessly recovers and returns valuable condensate to the boiler, minimizing energy waste. Crafted with precision, the unit ensures reliable operation, even in demanding industrial environments. Its intuitive design facilitates easy integration into existing setups, optimizing the entire steam system. By reclaiming and repurposing condensate, this unit not only enhances energy efficiency but also reduces operational costs. Elevate your sustainability efforts with our Condensate Recovery Unit a reliable, cost-effective, and eco-friendly solution for maximizing the potential of your steam system while minimizing environmental impact.

Specification

|

Brand |

IEPL |

|

Material |

MILD STEEL |

|

Model Name/Number |

1 TO 12 TPH |

|

Inlet Temperature |

80-100 C |

|

Outlet Temperature |

80-100 C |

|

Capacity |

1 TO 12 TPH |

|

COLOUR |

BLUE |

Customizable Design for Industrial Needs

Whether your steam system demands a compact 30L unit or a larger 500L solution, our Condensate Recovery Unit can be tailored for any requirement. Offered with both horizontal and vertical structures, and a choice of mild steel or high-grade stainless steel material, customization extends to inlet/outlet sizes and tank volume. The unit's flexibility guarantees suitability for a wide range of steam applications.

Efficient Operation and Energy Savings

Utilizing advanced centrifugal pump mechanisms with single or multistage options, this unit ensures continuous, efficient recovery of condensate. The corrosion-resistant, epoxy-coated paint or polished stainless steel finish guards against tough environments, while features such as self/manual priming and optional external insulation further optimize performance and minimize energy losses in steam system automation.

Reliable Onsite and After-Sales Support

Our commitment to customer satisfaction includes comprehensive onsite installation and after-sales service across India. Each unit is manufactured to IS/ISO standards for assured quality and safety. Whether installed indoors or outdoors, users benefit from low noise levels, straightforward installation, and ongoing technical assistance by experienced professionals.

FAQ's of Condensate Recovery Unit:

Q: How does the condensate recovery unit improve energy efficiency in steam systems?

A: By collecting and returning condensed steam to the boiler, the unit minimizes water and heat losses, reducing fuel consumption and operational costs. The centrifugal pump ensures swift transport of condensate, while features such as optional external insulation and corrosion-resistant components further enhance efficiency.Q: What installation options are available for this unit?

A: The unit is suitable for both indoor and outdoor installations and can be mounted on a base or skid as required. The design supports horizontal or vertical placement, and inlet/outlet connections are customizable to fit onsite requirements.Q: When should I choose a stainless steel float switch and level transmitter feedback system?

A: A stainless steel float switch offers robust and accurate liquid level detection, ideal for corrosive or high-temperature environments. The level transmitter feedback is optional and recommended for automated control systems where precise monitoring and integration with steam system automation is required.Q: Where is onsite after-sales support available for this product?

A: Onsite after-sales service covers various regions across India, ensuring prompt technical assistance with installation, maintenance, and troubleshooting by qualified service professionals.Q: What is the process for customizing the tank volume and configuration?

A: Customization begins with assessing your steam system's condensate volume and operational parameters. The unit's tank, inlet/outlet size, structural configuration, material, and control features are tailored according to your specific needs, followed by manufacturing and installation as per IS/ISO standards.Q: How can the unit be used in boiler feed and steam system automation?

A: It serves as a crucial component in boiler feed applications, efficiently collecting and transferring condensate. With its automatic/manual control system and compatibility with level transmitters, it seamlessly integrates into broader steam system automation, ensuring reliable and safe operation.Q: What are the key benefits of installing this condensate recovery unit?

A: The unit offers significant energy savings, lower operational costs, reduced environmental impact, and robust performance. Easy installation, low noise levels, compliance with IS/ISO standards, and access to reliable service further make it a dependable choice for exporters, manufacturers, and end-users.

Price 120000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Condensate Recovery System Category

Condensate Recovery System

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Steam Boiler Feed, Heat Recovery

Discharge Pressure : Up to 5 bar

Pressure : Other, Max 5 bar

Fuel Type : Other, Electric

Condensate Recovery Pump

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Steam Boiler Condensate Recovery

Discharge Pressure : Up to 4 bar

Pressure : Other, Up to 4 bar

Fuel Type : Other, Electric

Condensate Heat Recovery System

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Industrial Heat Recovery, Boiler Feed Water

Discharge Pressure : Up to 10 Bar

Pressure : Other, Up to 10 Bar

Fuel Type : Other, Electric

Automatic Condensate Pump

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other, Condensate Water Drainage

Discharge Pressure : Up to 1.2 bar

Pressure : Other, 0.12 MPa

Fuel Type : Other, Electric