High Condensate System for Steam

High Condensate System for Steam Specification

- Theory

- Centrifugal Pump

- Caliber

- 2550 mm

- Noise Level

- 70 dB

- Frequency

- 50/60 Hz

- Mounting Type

- Floor / Skid

- Features

- Energy Saving, Corrosion Resistant, Compact Design

- Max Suction

- 7 meters

- Head Size

- 855 meters

- Flow Rate

- 0.535 m/hr

- Inlet/Outlet

- DN25, DN40, DN50

- Working Temperature

- upto 180C

- Voltage

- 230V / 415V

- Control System

- PLC / Automatic

- Discharge Pressure

- Up to 8 bar

- Speed

- 2900 rpm

- Material

- SS304 / SS316 / Cast Iron

- Structure

- Compact Skid Mounted

- Power

- 0.75 kW to 11 kW

- Standard

- ISI / ISO 9001:2015

- Fuel Type

- Electric Driven

- Pressure

- Up to 8 bar

- Usage

- Steam Condensate Recovery

- Application

- Steam Boiler Condensate System

- Suction Type

- Horizontal

- Seals Type

- Mechanical Seal

- Priming

- Self Priming

- Pump Type

- Multistage / Single Stage

- Capacity

- 506000 kg/hr

- Pump Coupling

- Flexible Coupling

- Maintenance

- Low Maintenance

- Safety Valve

- Integrated

- Level Controller

- Electronic Level Transmitter

- Surface Finish

- Epoxy Powder Coated

- Flow Adjustment

- Variable via VFD

- Insulation

- Thermal Insulation Provided

- Cooling Method

- Air Cooled

- Installation

- Ready to Install

- Protection Class

- IP55 Motor Enclosure

- Service

- Onsite Commissioning & Support

- Ambient Temperature

- -10°C to 50°C

- Display

- Digital Panel Indication

- Drain Connection

- Provided at Skid

High Condensate System for Steam Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

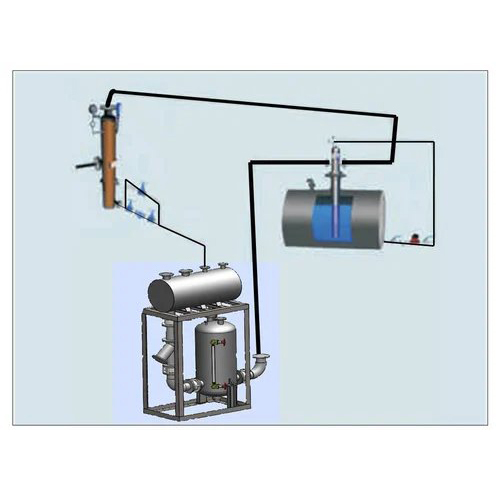

About High Condensate System for Steam

Our system excels at collecting and returning condensate to the boiler, ensuring minimal energy loss and optimal system performance. Crafted for durability, it seamlessly operates in diverse industrial environments, addressing the challenges of high condensate loads. The user-friendly design facilitates easy integration into existing setups, providing a robust solution for condensate management. By efficiently recovering and recycling condensate, our High Condensate System not only reduces operational costs but also champions sustainability, contributing to a greener industrial footprint. Upgrade your steam system with this dependable, high-performance solution.

Specification

|

Capacity |

1 ton to 12 |

|

Fuel |

not required |

|

Usage/Application |

Industrial |

|

Material |

Mild Steel |

|

Brand |

IEPL |

|

Working Pressure |

0-5 (kg/cm2g) |

|

Color |

BLUE |

|

I Deal In |

New Only |

|

Country of Origin |

Made in India |

Optimized for Industrial Steam Recovery

Our condensate system is designed for seamless integration with steam boilers, ensuring efficient recovery and reuse of condensate. The flexible coupling and self-priming centrifugal pump provide reliable operation, while the compact, skid-mounted design enables easy installation. This minimizes downtime and maximizes process efficiency for industries seeking energy savings and improved water management.

Advanced Automation and Control

Equipped with a PLC-based automatic control system, digital panel indication, and electronic level transmitter, this unit guarantees precise and safe operation. The variable frequency drive (VFD) allows users to easily adjust flow rates, making it versatile for varying process demands. Safety features, including integrated valves and electronic monitoring, promote operational security and reliability.

Durable Design for Diverse Environments

Constructed with high-quality SS304, SS316, or cast iron, and coated with epoxy powder, this system resists corrosion and is suitable for rigorous industrial conditions. Its operation is quiet (70 dB) and energy-efficient, supporting sustainable industrial processes. The IP55 motor enclosure and thermal insulation ensure safe and stable performance in ambient temperatures from -10C to 50C.

FAQ's of High Condensate System for Steam:

Q: How is the High Condensate System installed?

A: The system is delivered as a compact, skid-mounted unit, fully ready for installation. Floor mounting is supported, and the drain connection, power supply (230V/415V), and control interfaces are pre-integrated for hassle-free setup.Q: What are the main benefits of using this condensate recovery system?

A: Key benefits include energy savings, lower water consumption, efficient condensate recovery, corrosion resistance, and minimal maintenance. Its advanced controls and automation maximize operational reliability and process efficiency.Q: When should the flow rate be adjusted in this system?

A: Flow rate adjustments are typically made to suit process variations or optimize energy usage. The integrated VFD enables precise flow management between 0.5-35 m3/hr, adapting to seasonal, production, or boiler load changes.Q: Where is this condensate system commonly used?

A: This unit is commonly utilized in steam boiler rooms, process plants, and industries where steam condensate requires efficient recovery and reuse, contributing to reduced operational costs and environmental impact.Q: What process controls and safety features are provided in the system?

A: The system includes a PLC control system, electronic level transmitter, digital panel display, integrated safety valve, and thermal insulation. These features ensure safe operation, maintain required pressures, and enable continuous electronic monitoring.Q: How does the system maintain low noise and safe operation?

A: Operating at noise levels 70 dB, supported by IP55 motor protection and vibration dampening, the system offers quiet and secure performance even in demanding environments. Continuous digital monitoring further enhances safety.Q: What support is available after installation?

A: Onsite commissioning and technical support are provided, including setup, testing, and operator training. Ongoing service is available for troubleshooting, maintenance, and system optimization.

Price 160000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Condensate Recovery System Category

Condensate Recovery Unit

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : As per requirement (customized)

Caliber : Standard/Custom sizes

Theory : Centrifugal Pump

Pressure : Other, Up to 6 kg/cm

Pressure Powered Pump

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 1025 m/h

Caliber : 50 mm

Theory : Centrifugal Pump

Pressure : Other, 1.05.0 bar

Condensate Recovery

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 3 m/h

Caliber : 25 mm

Theory : Centrifugal Pump

Pressure : Other, Up to 3 bar

Condensate Return Unit

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 30 to 1000 LPH

Caliber : DN25DN50

Theory : Centrifugal Pump

Pressure : Other, Up to 4 bar