Condensate Return Unit

Condensate Return Unit Specification

- Max Suction

- 4-6 meters

- Frequency

- 50/60 Hz

- Discharge Pressure

- Max 4 bar

- Working Temperature

- Up to 100C

- Caliber

- DN25-DN50

- Noise Level

- < 70 dB

- Theory

- Centrifugal Pump

- Control System

- Automatic/Manual

- Features

- Corrosion Resistant, Energy Efficient, Compact Design

- Head Size

- 10-45 meters

- Mounting Type

- Floor Mounted

- Speed

- 1440/2880 RPM

- Inlet/Outlet

- 1 to 2 BSP/NPT

- Voltage

- 220-415 V

- Flow Rate

- 0.5 to 10 m/hr

- Material

- Mild Steel/SS304/SS316

- Structure

- Horizontal Base Mounted

- Power

- 0.5-5 HP

- Standard

- ISO 9001:2015

- Fuel Type

- Electric

- Pressure

- Up to 4 bar

- Usage

- Condensate Recovery

- Application

- Boiler Feed, Heating Systems

- Suction Type

- Direct Suction

- Seals Type

- Mechanical Seal

- Priming

- Self Priming available

- Pump Type

- Centrifugal/Multistage

- Capacity

- 30 to 1000 LPH

Condensate Return Unit Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Condensate Return Unit

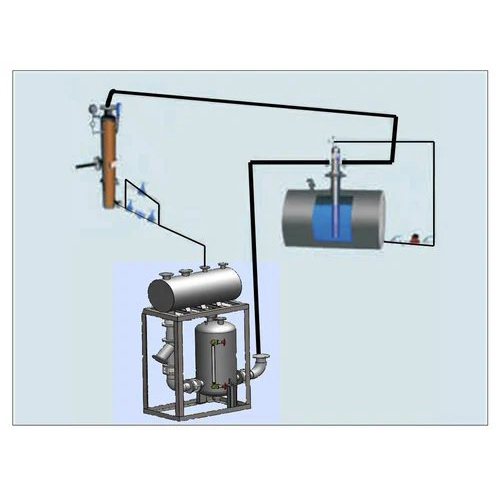

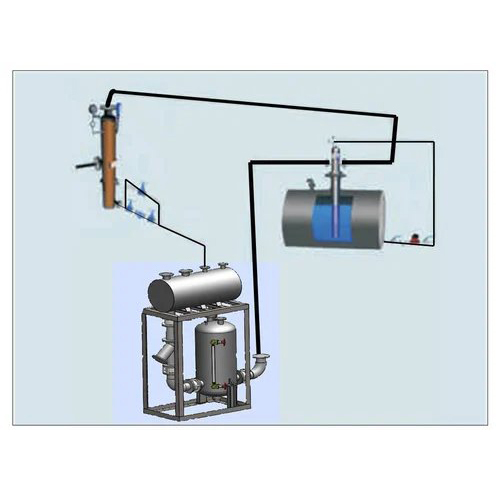

Introducing our Condensate Return Unit a vital component for steam system optimization Engineered for efficiency this unit adeptly collects and returns condensate to the boiler minimizing energy loss and enhancing overall system performance Robust in construction it ensures durability across diverse industrial environments The userfriendly design streamlines integration into existing setups offering a seamless solution for condensate management By recovering and reusing condensate effectively the unit not only trims operational costs but also aligns with sustainability goals reducing environmental impact Elevate your steam systems efficiency with our Condensate Return Unit a reliable costeffective and environmentally conscious solution for fluid management

Specification

|

Brand |

IEPL |

|

Material |

MILD STEEL |

|

Model Name/Number |

1 TO 12 TPH |

|

Inlet Temperature |

80-100 C |

|

Outlet Temperature |

80-100 C |

|

Working Pressure |

4.5 KG AIR OR STEAM |

Robust Construction and Versatile Capacity

Built with corrosion-resistant materials such as Mild Steel or stainless steel, our condensate return units come in capacities from 40 to 500 liters. Powder coated or enamel finishes ensure long-lasting performance, even in demanding environments.

High-Performance Pumping for Continuous Duty

The centrifugal pump, driven by a reliable electric motor, provides continuous operation. Self-priming and direct suction features ensure efficient condensate recovery, supporting head sizes up to 45 meters and flow rates between 0.5 to 10 m3/hr.

Advanced Features for Enhanced Efficiency

With an automatic or manual control system, IP 55 protection, and energy-efficient build, the unit offers safe and optimized operation. Its compact, floor-mounted design and noise level below 70 dB allow for flexible installation and minimal disruption.

FAQ's of Condensate Return Unit:

Q: How does the condensate return unit improve energy efficiency in boiler feed systems?

A: By recovering and returning hot condensate to boilers, the unit significantly reduces fresh water and fuel consumption, lowering overall energy costs and enhancing system sustainability.Q: What material options are available for the tank and pump assembly?

A: The unit can be constructed from Mild Steel, SS304, or SS316 stainless steels, enabling selection based on corrosion resistance, application requirements, and durability.Q: When should I opt for a self-priming condensate return unit?

A: A self-priming unit is ideal when immediate automatic operation is necessary, especially in installations where suction lifts up to 4-6 meters are present, eliminating the need for manual intervention.Q: Where can these units be installed within an industrial facility?

A: The condensate return units are designed for floor mounting and are suitable for installation beside boilers, heat exchangers, or any location requiring condensate collection and return.Q: What process is involved in the maintenance of the condensate return unit?

A: Routine inspection includes checking the mechanical seals, monitoring electrical connections, cleaning the tank, and ensuring proper function of automatic controls to maintain optimal performance.Q: How is the unit protected against rough environments and electrical hazards?

A: The unit features an IP 55 protection class, robust powder-coated or enamel finish, and corrosion-resistant materials, safeguarding against water ingress, dust, and harsh industrial conditions.Q: What are the main benefits of using your condensate return system?

A: Key benefits include improved energy efficiency, compact and quiet design, reliable continuous-duty performance, customizable controls, and compliance with international standards like ISO 9001:2015.

Price 120000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Condensate Recovery System Category

Condensate Heat Recovery System

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Seals Type : Mechanical Seal

Fuel Type : Other, Electric

Application : Other, Industrial Heat Recovery, Boiler Feed Water

Control System : Automatic/PLC Controlled

High Condensate System for Steam

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Seals Type : Mechanical Seal

Fuel Type : Other, Electric Driven

Application : Other, Steam Boiler Condensate System

Control System : PLC / Automatic

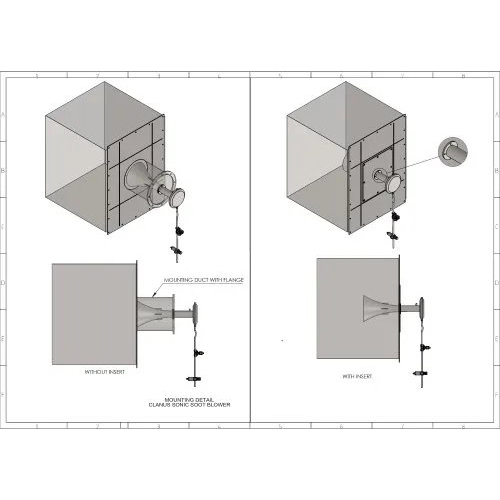

Sonic Soot Blowers For Bag Filter

Price 10000 INR / Unit

Minimum Order Quantity : 1 Unit

Seals Type : High Temperature Resistant Seals

Fuel Type : Other, Electric

Application : Other

Control System : PLC Based / Timer Controlled