Steam Powered Pump

Steam Powered Pump Specification

- Mounting Type

- Baseplate Mounted

- Head Size

- Up to 95 meters

- Speed

- 200 - 350 RPM

- Working Temperature

- Up to 180C

- Control System

- Manual/Automatic Options

- Caliber

- 50-150 mm

- Inlet/Outlet

- Customizable Flanges, typically 2 to 6

- Features

- Self-priming, corrosion resistant, operates without electric power

- Voltage

- Not Applicable (Steam Operated)

- Flow Rate

- Up to 28 m/hr

- Discharge Pressure

- Up to 16 kg/cm

- Noise Level

- Low

- Theory

- Reciprocating Pump

- Max Suction

- Up to 8 meters

- Material

- Cast Iron/Steel/Alloy

- Structure

- Double Acting Piston Type

- Power

- Steam Driven

- Standard

- IS/ISO Standard

- Fuel Type

- Steam

- Pressure

- Up to 16 Bar

- Usage

- Water Supply, Boiler Feed, Irrigation, Industrial

- Application

- Chemical Industry, Boiler Feed, Oil & Gas, Marine, Mining

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal

- Priming

- Self-Priming

- Pump Type

- Steam Powered Reciprocating Pump

- Capacity

- Upto 28 m/hr

- Max Steam Pressure

- Up to 20 Bar

- Stroke Length

- Up to 250 mm

- Weight

- Approx. 250 kg 880 kg (model dependent)

- Service Life

- Designed for continuous duty

- Number of Cylinders

- Single/Double Cylinder

- Temperature Range

- Ambient to 180C

- Lubrication Type

- Forced Lubrication System

- Surface Finish

- Corrosion Resistant Coating

- Installation Position

- Horizontal

- Drive Arrangement

- Direct Coupled or Belt Driven

- Minimum Steam Consumption

- 3 kg/h (varies with model)

Steam Powered Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Steam Powered Pump

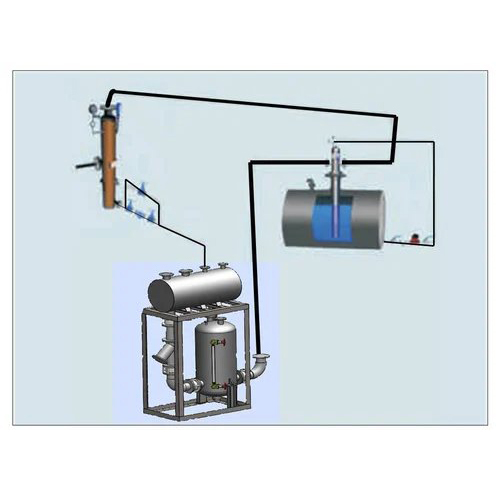

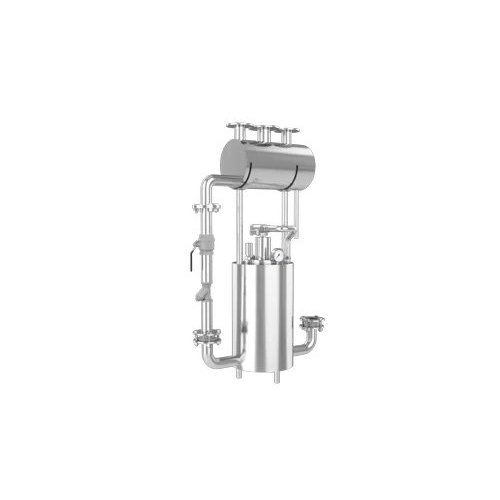

Introducing our Steam-Powered Pump, a pioneering solution for versatile fluid transfer in industrial settings. Harnessing the power of steam, this pump exemplifies efficiency and sustainability. The innovative design seamlessly integrates with steam systems, utilizing the thermal energy to drive the pump. Its robust construction ensures durability in demanding environments, providing a reliable solution for various fluid-handling applications. Installation is streamlined for convenience, making it an ideal choice for both new and existing setups. Experience enhanced operational efficiency with our Steam-Powered Pump, delivering a cost-effective and environmentally conscious approach to fluid transfer, while maximizing the potential of your steam infrastructure.

Specification

|

Material |

Mild Steel |

|

Model Name/Number |

1 TO 12 TPH |

|

Pump Type |

ELECTROMECHANICAL |

|

Usage/Application |

CONDENSATE RECOVERY PUMP |

|

Color |

BLUE |

|

Country of Origin |

Made in India |

Exceptional Adaptability and Robust Design

The steam powered pump boasts a flexible configuration, supporting both direct-coupled and belt-driven arrangements. It efficiently operates in horizontal installations, powered solely by steam up to 20 bar, requiring no electricity. Its cast iron, steel, or alloy construction and corrosion-resistant finish ensure longevity in demanding industrial settings, minimizing maintenance and downtime.

Reliable Performance Across Industries

Designed for water supply, boiler feed, irrigation, and industrial applications, this pump's double acting piston structure handles up to 28 m3/hr flow and 95 meter heads. With self-priming capability and forced lubrication, it maintains smooth operation under fluctuating loads and is compliant with IS/ISO standards for quality and safety. Customizable inlet/outlet flanges fit various system requirements.

FAQ's of Steam Powered Pump:

Q: How does the steam powered reciprocating pump operate without electricity?

A: This pump utilizes steam as its primary driving force. The reciprocating action is powered by steam pressure entering the cylinder, making the pump independent of electrical energy and ideal for remote or hazardous environments where electricity access is limited or undesirable.Q: What are the main benefits of using a steam powered pump in industrial applications?

A: Steam powered pumps offer robust, continuous-duty operation, low noise levels, and adaptability to high-temperature fluids. Their corrosion-resistant coatings and mechanical seals ensure longevity, while forced lubrication maintains reliable performance during extended use. The pump also complies with IS/ISO standards, guaranteeing safety and reliability.Q: Where can the steam powered pump be installed and used effectively?

A: This pump is baseplate mounted for stable horizontal installation and is suitable for chemical processing, boiler feeding, irrigation, oil & gas, marine, mining, and industrial water supply. Its customizable flange design allows integration into diverse pipeline systems.Q: What is the typical process for starting and operating this pump?

A: To operate, connect the pump's steam inlet to the steam supply (up to 20 bar), ensure water source is primed, and select manual or automatic control. The pump uses forced lubrication to protect internal components and can deliver flow rates up to 28 m3/hr, depending on your model and application needs.Q: How is the maintenance of the steam powered pump managed for continuous duty?

A: Maintenance involves periodic inspection of mechanical seals, lubrication systems, and corrosion-resistant coatings. The forced lubrication system minimizes wear, requiring routine checks of oil levels and seal integrity. Baseplate mounting and accessible design facilitate straightforward servicing and component replacement.Q: What customizable options are available for the pump's inlet and outlet connections?

A: The pump supports customizable flanges, typically with 2 to 6 ports and caliber sizes ranging from 50-150 mm. This allows it to be readily tailored to specific system requirements, ensuring compatibility with various industrial setups and piping arrangements.

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Condensate Recovery System Category

Pressure Power Pump

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Seals Type : Mechanical Seal

Mounting Type : Base Mount

Suction Type : Single Suction

Head Size : 35 meters

Steam Condensate Recovery System

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Seals Type : Mechanical Seal

Mounting Type : Floor Mounted

Suction Type : Positive Suction

Head Size : 25 m

Automatic Stainless Steel Mechanical Power Pressured Pump

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Seals Type : Mechanical Seal

Mounting Type : Floor Mounted

Suction Type : SelfPriming

Head Size : 28 meters

Steam Condensate Return Pump

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Seals Type : Mechanical Seal

Mounting Type : Basemounted / Skidmounted

Suction Type : Side or End Suction

Head Size : Up to 40 m