Steam Condensate Recovery System

Steam Condensate Recovery System Specification

- Control System

- Automatic Control Panel

- Theory

- Steam Condensate Recovery and Reuse

- Flow Rate

- Up to 10 m/hr

- Features

- Energy Saving, Corrosion Resistance, Low Maintenance

- Mounting Type

- Floor Mounted

- Caliber

- DN32 inlet

- Noise Level

- <70 dB(A)

- Max Suction

- 6 m

- Voltage

- 415 V AC, 3-Phase

- Frequency

- 50 Hz

- Working Temperature

- Up to 120C

- Head Size

- 25 m

- Speed

- 2900 RPM

- Inlet/Outlet

- DN32 / DN25 (Customizable)

- Discharge Pressure

- Up to 5 bar

- Material

- SS304/SS316

- Structure

- Compact Skid Mounted Unit

- Power

- 1.5 kW - 5 kW

- Standard

- ISI / IEC / ASME

- Fuel Type

- Electric

- Pressure

- Up to 7 bar

- Usage

- Industrial Steam Systems

- Application

- Steam Condensate Recovery, Boiler Feedwater

- Suction Type

- Positive Suction

- Seals Type

- Mechanical Seal

- Priming

- Self-priming or External

- Pump Type

- Centrifugal/Multistage

- Capacity

- Up to 1000 LPH

- Pipe Connection Type

- Flanged / Threaded

- Safety Interlocks

- Included for dry run & overpressure

- Lifecycle

- >10 years with regular maintenance

- Enclosure Material

- Powder Coated Mild Steel

- Local/Remote Operation

- Supported

- Ambient Temperature

- Up to 50°C

- System Integration

- Can be integrated with PLC/DCS

- Protection Class

- IP55

- Flow Measurement

- Integrated Flow Meter

- Installation Mode

- Ready to use Plug & Play

- Drain Connection

- Provided

- Monitoring

- Digital Level & Pressure Sensors

- Backflow Preventer

- Integrated Non-Return Valve

- Service Support

- On-site & Remote Assistance

Steam Condensate Recovery System Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Steam Condensate Recovery System

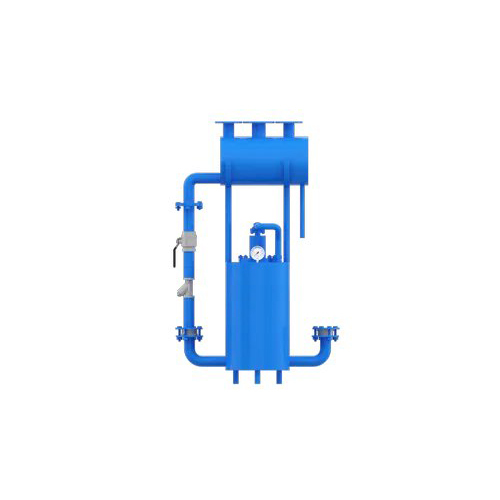

Introducing our Steam Condensate Recovery System, a cornerstone for sustainable steam operations. This system excels in collecting and returning condensate to the boiler, preventing energy wastage and optimizing overall system performance. Engineered for reliability and durability, it operates seamlessly across diverse industrial environments. The user-friendly design facilitates easy integration into existing setups, providing a streamlined solution for condensate management. By effectively reclaiming and recycling condensate, our system not only reduces operational costs but also aligns with sustainability goals, minimizing environmental impact. Elevate your steam system with our dependable, cost-effective, and environmentally conscious Steam Condensate Recovery System.

Specification

|

Brand |

Innovative Enerpro pvt.ltd |

|

Material |

Mild steel |

|

Voltage |

230 V |

|

Capacity |

1 ton to 12 ton |

|

Working Pressure |

Steam Or Air |

|

Country of Origin |

Made in India |

Plug & Play Installation for Rapid Deployment

Our system's ready-to-use, plug & play design simplifies commissioning and installation. With all essential connections-including flanged or threaded pipe fittings-pre-configured, the unit can be quickly integrated into existing industrial steam networks. The compact, floor-mounted skid structure saves space and minimizes setup time, making it suitable for both brownfield and greenfield projects.

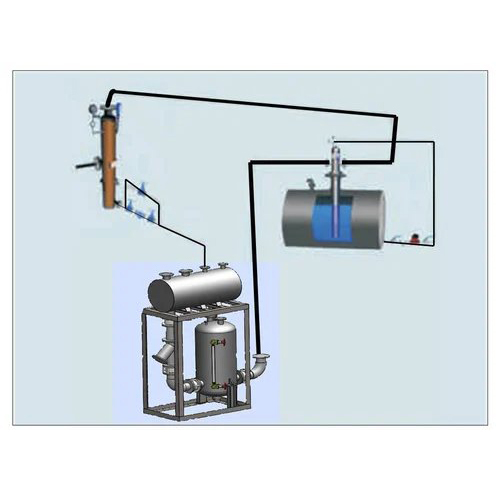

Monitoring & Control: Advanced Automation

Smart monitoring via digital level and pressure sensors is complemented by a fully automatic control panel. The system is compatible with PLC/DCS for remote or local supervision, enabling real-time performance tracking and alerts. Integrated safety features, such as interlocks for dry run and overpressure, uphold operational integrity and protect equipment.

Durable, Energy-Efficient Performance

Engineered for reliability, the powder-coated mild steel enclosure assures IP55 protection, while internal components utilize high-grade SS304/SS316 for corrosion resistance. The centrifugal/multistage pump delivers up to 25m head and 10 m3/hr flow, powered by a robust 1.5-5 kW motor. This configuration guarantees efficient condensate recovery, extended lifecycle, low noise emissions, and significant energy savings.

FAQ's of Steam Condensate Recovery System:

Q: How does the Steam Condensate Recovery System protect against backflow and ensure safe operation?

A: This recovery system features an integrated non-return valve (backflow preventer) and includes safety interlocks for dry run and overpressure conditions. These measures safeguard the system and connected equipment from reverse flow or unsafe operating states.Q: What process does the system use to recover and reuse steam condensate in industrial steam setups?

A: Steam is condensed and collected via positive suction and self-priming pump action. The recovered condensate passes through filtration and measurement stages before being transferred for boiler feedwater reuse or other industrial processes, maximizing water and energy conservation.Q: Where can the Steam Condensate Recovery System be installed, and is it suitable for harsh environments?

A: The system is designed for floor mounting in industrial environments. The IP55-rated, powder-coated mild steel enclosure protects it against dust and water ingress, while it operates efficiently in ambient temperatures up to 50C and working temperatures up to 120C.Q: What are the main benefits of using this system for condensate recovery?

A: Key benefits include significant energy saving, reduced water consumption, corrosion resistance, low maintenance, efficient condensate reuse, and extended system lifespan with reliable service support. Integrated automation further optimizes operations and minimizes labor costs.Q: How can the system be monitored and operated, both locally and remotely?

A: Operators can monitor and control the unit using the automatic control panel onsite or through digital level and pressure sensors integrated with PLC/DCS for remote supervision. Real-time system data and alarms enable swift response and effective management.Q: When should regular maintenance be performed to ensure optimal system performance?

A: Routine maintenance, such as inspecting seals, checking sensor calibration, cleaning filters, and general system health checks, should be carried out according to manufacturer recommendations-typically semi-annually-to ensure reliable operation and maximize the system's lifecycle beyond 10 years.Q: What support is available for installation and servicing of the Steam Condensate Recovery System in India?

A: Comprehensive on-site and remote assistance is offered by the manufacturer, exporter, and supplier, ensuring expert installation, integration, troubleshooting, and lifecycle support for customers across India.

Price 150000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Condensate Recovery System Category

Condensate Pump

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Other, 25 Watts

Seals Type : Mechanical Seal

Pump Type : Other, Mini Condensate Pump

Head Size : 10 meters

Mechanical SS Condensate Recovery Pump

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Other, 0.75 kW, 1.5 kW, 2.2 kW

Seals Type : Mechanical Seal

Pump Type : Other, Horizontal

Head Size : Up to 35 m

Boiler Condensate Pump

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Other, 0.754 kW

Seals Type : Mechanical Seal

Pump Type : Centrifugal Condensate Pump, Other

Head Size : 1555 m

Pressure Powered Pumping Packaged Unit

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Other, 0.37 kW to 5.5 kW

Seals Type : Mechanical Seal

Pump Type : Other, Pressure Powered Pump

Head Size : 10 m to 35 m