Sonic Soot Blowers For Bag Filter

Sonic Soot Blowers For Bag Filter Specification

- Theory

- Acoustic Cleaning

- Caliber

- DN50/DN100

- Features

- Low Maintenance, Non-Intrusive Cleaning, Reduces Downtime

- Discharge Pressure

- 0.5 MPa to 0.8 MPa

- Working Temperature

- -20C to +80C Celsius (oC)

- Inlet/Outlet

- Customizable Flange Connections

- Control System

- PLC Based / Timer Controlled

- Noise Level

- < 120 dB(A) db

- Voltage

- 220 V / 380 V Volt (v)

- Frequency

- 50/60 Hz Hertz (HZ)

- Speed

- Fixed, On/Off Controlled Km/s

- Mounting Type

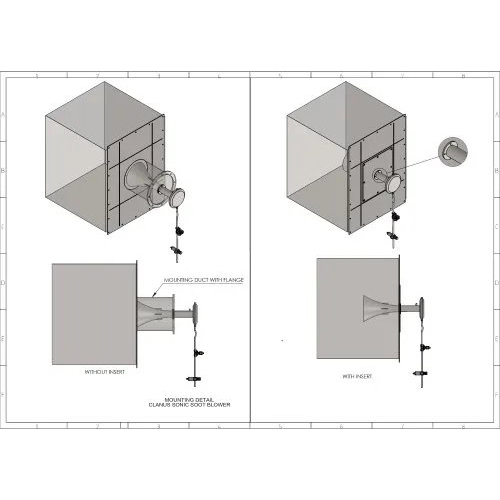

- Horizontal / Vertical Mounting

- Material

- Stainless Steel / Carbon Steel

- Structure

- Horn Type with Solenoid Valve

- Power

- 120 W to 500 W

- Standard

- ISO/CE Certified

- Fuel Type

- Electric

- Pressure

- 0.5 MPa to 0.8 MPa (Operating Air)

- Usage

- Other

- Application

- Other

- Seals Type

- High Temperature Resistant Seals

- Capacity

- Depends on Model and Application Kg/hr

- Installation

- Retrofit and New Projects

- Maintenance

- Low, No moving parts exposed

- Body Finish

- Corrosion Resistant Coated

- Air Connection

- or BSP

- Operating Principle

- Pulsed Sonic Sound Wave

- Horn Diameter

- 250 mm / 380 mm (Standard Sizes)

- Safety

- Integrated Pressure Relief and Silencing

- Sound Output

- Up to 135 dB

Sonic Soot Blowers For Bag Filter Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Sonic Soot Blowers For Bag Filter

Introducing our Sonic Soot Blowers for Bag Filter a revolutionary solution for efficient and noncontact cleaning in industrial filtration systems This cuttingedge technology employs powerful sonic waves to dislodge and remove stubborn soot deposits from bag filters ensuring peak filtration performance The nonintrusive cleaning process minimizes wear and tear on filter components extending their lifespan and reducing maintenance costs With precise and controlled sonic vibrations our Soot Blowers enhance bag filter efficiency promoting uninterrupted air quality control in various industrial applications Elevate your filtration system with the Sonic Soot Blowers a highperformance lowmaintenance solution for optimal bag filter operation

Specification

|

Material |

Stainless Steel |

|

Model/Type |

CSSB 240 HZ / 120 HZ / 75HZ |

|

Product Type |

CLEANING PURPOSE |

|

Capacity |

Ahmedabad |

|

Country of Origin |

Made in India |

Efficient Non-Intrusive Cleaning

The Sonic Soot Blower utilizes powerful pulsed sonic waves to dislodge particulate build-up from surfaces within bag filters, silos, and hoppers. Its innovative design eliminates mechanical impact, ensuring continuous operation and preserving equipment longevity while minimizing manual intervention and downtime.

Robust Construction for Demanding Environments

Crafted from stainless steel or carbon steel and coated for corrosion resistance, the blower operates efficiently in rigorous industrial conditions, including temperatures ranging from -20C to +80C. High-temperature-resistant seals and customizable flange connections promote reliable performance in a variety of installations.

Versatile Installation and Control

Whether for retrofitting existing plants or incorporating into new projects, this blower is adaptable with customizable air connections and horizontal or vertical mounting. Operation can be managed via PLC-based or timer-controlled systems, offering seamless integration with plant automation protocols.

FAQs of Sonic Soot Blowers For Bag Filter:

Q: How does the Sonic Soot Blower clean bag filters and industrial equipment?

A: The blower operates by emitting high-intensity pulsed sonic sound waves, which create vibrations that dislodge dust and particulate matter from surfaces like bag filters, hoppers, and silos. This acoustic cleaning method is non-intrusive and avoids the wear and tear associated with mechanical methods.Q: What are the main usage benefits of installing this sonic soot blower?

A: Installing the Sonic Soot Blower offers significant benefits such as reduced maintenance requirements, minimized equipment downtime, enhanced cleaning efficiency, and improved air flow. Its non-intrusive operation preserves filter life and supports continuous system performance.Q: When is it recommended to use a sonic soot blower over traditional cleaning methods?

A: A sonic soot blower is ideal when you require non-intrusive, low-maintenance cleaning, especially in environments with sensitive or hard-to-reach surfaces. It is particularly beneficial for continuous processes where frequent shutdowns for manual cleaning are not feasible.Q: Where can the Sonic Soot Blower be installed within an industrial facility?

A: This blower can be installed in baghouses, electrostatic precipitators, hoppers, and silos. Its design supports both retrofit projects and new installations, and it can be mounted either horizontally or vertically, making it versatile for a range of plant layouts.Q: What ensures the safety and reliability of this equipment during operation?

A: Safety is ensured by integrated pressure relief and silencing systems. The blower has no exposed moving parts, and its construction from corrosion-resistant materials and high-temperature seals guarantees reliable and safe functioning in demanding environments.Q: Can the Sonic Soot Blowers connection interfaces be customized?

A: Yes, the unit offers customizable flange connections and a choice of air inlets ( or BSP) to suit specific installation requirements. Models are available in DN50 and DN100 calibers to match different system sizes.

Price 10000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Condensate Recovery System Category

Condensate Recovery System

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Fuel Type : Other, Electric

Suction Type : Horizontal

Priming : Self Priming

Head Size : Up to 38 m

Condensate Recovery

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Fuel Type : Other, Electric

Suction Type : Single Suction

Priming : Self Priming

Head Size : Up to 30 m

Condensate Heat Recovery System

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Fuel Type : Other, Electric

Suction Type : Horizontal / Vertical

Priming : SelfPriming / Manual Priming

Head Size : Up to 35 m

Steam Condensate Return System

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Fuel Type : Other, Electric

Suction Type : Direct Suction

Priming : Self / Manual Priming

Head Size : 530 meters