Mechanical SS Condensate Recovery Pump

Mechanical SS Condensate Recovery Pump Specification

- Max Suction

- 6 m

- Flow Rate

- Up to 2-10 m/h

- Control System

- On/Off with Level Controller

- Caliber

- 25 mm

- Noise Level

- Low Noise: < 75 dB(A)

- Head Size

- Up to 35 m

- Inlet/Outlet

- 25 mm / 25 mm

- Voltage

- 220V / 380V

- Speed

- 2900 RPM

- Theory

- Centrifugal Pump

- Frequency

- 50 Hz

- Features

- Corrosion resistant, Maintenance free, High efficiency

- Working Temperature

- Up to 120C

- Discharge Pressure

- Up to 4 kg/cm

- Mounting Type

- Base Mounted

- Material

- Stainless Steel SS-304 / SS-316

- Structure

- Single Stage

- Power

- 0.75 kW, 1.5 kW, 2.2 kW

- Standard

- IS & DIN

- Fuel Type

- Electric

- Pressure

- 2.5 to 4 kg/cm

- Usage

- Condensate Water Recovery

- Application

- Boiler Condensate Recovery

- Suction Type

- Negative Suction (Condensate recovery)

- Seals Type

- Mechanical Seal

- Priming

- Self Priming

- Pump Type

- Horizontal

- Capacity

- 2 m/h to 10 m/h

- Discharge Connection

- Threaded or Flanged

- Motor Protection

- IP55

- Max Liquid Viscosity

- Up to 50 cP

- Pump Painting

- SS Polished Body

- Max Allowable Ambient Temperature

- 50°C

- Operational Life

- Over 20,000 hours

- Electrical Connection

- Direct On-Line Starter

- Impeller Type

- Closed or Semi-open

- Max Liquid Density

- Up to 1.1 g/cm³

- Bearings

- Heavy Duty Ball Bearings

Mechanical SS Condensate Recovery Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Mechanical SS Condensate Recovery Pump

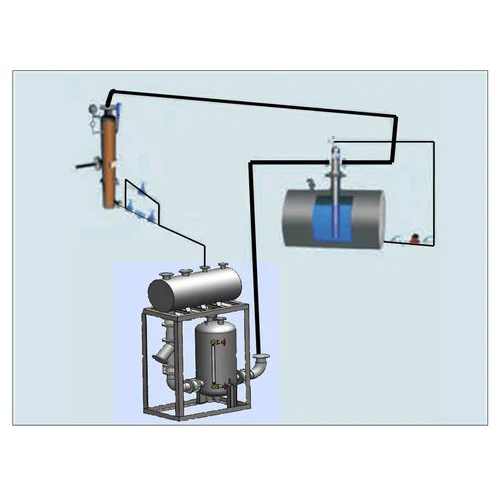

Introducing our Mechanical Stainless Steel (SS) Condensate Recovery Pump, an exceptional solution for optimizing steam system efficiency. Crafted with precision and durability in mind, this pump is designed to recover and return condensate, minimizing energy loss and enhancing overall system performance. The stainless steel construction ensures resilience in corrosive environments. With user-friendly features, it seamlessly integrates into existing setups, offering a reliable solution for condensate management. By effectively reclaiming and recycling condensate, this pump not only reduces operational costs but also contributes to sustainability goals, making it an ideal choice for industries prioritizing efficiency and environmental consciousness. Upgrade your steam system with our Mechanical SS Condensate Recovery Pump.

Specification

|

Model Name/Number |

MS Mechanical Condensate Recovery Pump |

|

Brand |

IEPL |

|

Capacity |

1 to 12 TPH |

|

Material |

S S |

|

Temperature |

up to 150 Degree |

|

Type |

Mechanical |

|

Country of Origin |

Made in India |

High-Performance and Long-Lasting Operation

Built for demanding industrial applications, the pump boasts an operational life beyond 20,000 hours thanks to precision engineering, SS body, and heavy-duty ball bearings. Its self-priming ability and negative suction design streamline condensate recovery, while motor protection rated at IP55 ensures enduring performance under harsh conditions.

Versatile Configuration for Varied Applications

The pump is designed for flexibility, supporting both threaded and flanged discharge options. With capacity ranging from 2 m3/h to 10 m3/h, adjustable power (0.75 kW, 1.5 kW, 2.2 kW), and compatibility with different liquid viscosities and densities, it suits a wide range of process and boiler condensate recovery settings.

Efficient and Reliable Control System

A direct on-line starter and integrated level controller provide straightforward operation and protection. The stainless-steel polished body ensures durability and corrosion resistance, while low noise output (<75 dB(A)) contributes to a safer, quieter work environment.

FAQ's of Mechanical SS Condensate Recovery Pump:

Q: How does the Mechanical SS Condensate Recovery Pump enhance boiler condensate recovery processes?

A: The pump's self-priming and negative suction capabilities efficiently draw and recover condensate from boiler systems, minimizing water loss and energy consumption. Heavy-duty bearings and durable mechanical seals ensure sustained, leak-proof operation, resulting in higher recovery rates and reliable system performance.Q: What are the main benefits of the stainless steel polished body?

A: The SS polished body offers exceptional corrosion resistance and long-term durability, significantly reducing maintenance needs and extending the pump's operational life. Its polished surface also supports hygienic operations and maintains structural integrity even under high temperature and pressure conditions.Q: When should the mechanical seal be inspected or replaced?

A: It is advisable to inspect the mechanical seal during routine maintenance cycles or when leakage or pressure drops are observed. The pump is designed for extended operational life (over 20,000 hours), but regular inspections help ensure optimal performance and prevent unexpected downtime.Q: Where is the best installation location for this condensate recovery pump?

A: For optimal performance, the pump should be base-mounted near the boiler system, with secure inlet/outlet connections and adequate ventilation. Its IP55 motor protection allows installation in industrial environments with moderate exposure to dust and moisture.Q: What is the process for starting and controlling the pump?

A: The pump utilizes a direct on-line starter for safe and easy electrical connection. Its built-in level controller provides automatic on/off operation, ensuring the system runs efficiently and responds to fluctuating condensate levels without manual intervention.Q: How can users benefit from the pump's maintenance-free design?

A: The robust construction using stainless steel and heavy-duty bearings minimizes wear and frequent servicing. This, combined with the mechanical seal and corrosion resistance, results in lower operating costs and a reliable, high-efficiency pump with minimal maintenance requirements.Q: Is the pump suitable for high temperature and variable liquid conditions?

A: Yes, the pump can handle working temperatures up to 120C and supports liquid viscosities up to 50 cP and densities up to 1.1 g/cm3. These features make it ideal for condensate recovery applications in demanding boiler operations.

Price 100000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Condensate Recovery System Category

Condensate Recovery Unit

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Structure : Other, Horizontal/Vertical

Application : Other, Boiler Feed, Steam System Automation

Noise Level : Low (<70 dB)

Control System : Automatic/Manual

Automatic Condensate Pump

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Structure : Other, Singlestage Pump

Application : Other, Condensate Water Drainage

Noise Level : 22 dB(A)

Control System : Float Switch

Steam Condensate Return System

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Structure : Other, Mounted Skid, Complete Assembly

Application : Other, Boiler Feed, Steam Condensate Return

Noise Level : <70 dB(A)

Control System : Float Switch / Level Control

Pressure Powered Condensate Pump

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Structure : Other, Horizontal, Pressure Vessel with Internal Mechanism

Application : Other, Industrial Steam Plants, HVAC, Chemical, Pharmaceutical, Food & Beverage

Noise Level : Below 70 dB (A)

Control System : Mechanical Float or Level Control