Steam Powered Condensate Pump

Steam Powered Condensate Pump Specification

- Head Size

- Up to 8 meters

- Voltage

- Not applicable (Steam operated)

- Caliber

- DN25

- Control System

- Mechanically actuated float

- Max Suction

- 6 meters

- Features

- Maintenance free, No electrical hazards, Automatic operation

- Speed

- Variable with Steam Pressure

- Working Temperature

- Up to 190C

- Discharge Pressure

- Up to 6 kg/cm

- Flow Rate

- 800 LPH to 2500 LPH

- Theory

- Reciprocating Condensate Transfer

- Noise Level

- Low, < 70 dB

- Mounting Type

- Floor / Skid Mounted

- Inlet/Outlet

- Flanged, 25 mm / 25 mm

- Material

- Cast Iron / Stainless Steel

- Structure

- Double Chamber with Float Mechanism

- Power

- Steam Paddle - No Electric Power

- Standard

- ASME/ISO 9001

- Fuel Type

- Steam

- Pressure

- Max 6 kg/cm Steam Pressure

- Usage

- Condensate Recovery, Boiler Feed

- Application

- Process Industry, Chemical, Textile

- Suction Type

- Positive Displacement

- Seals Type

- Graphite or PTFE

- Priming

- Self-Priming

- Pump Type

- Steam Operated Condensate Pump

- Capacity

- Up to 2500 lph

- Safety Devices

- Temperature and pressure relief valves

- Corrosion Protection

- Epoxy coated internal surfaces

- Weight

- Approx. 75 kg (varies with material)

- Ambient Temperature Range

- 0°C to 50°C

- Lifespan

- Design life 10+ years

- Backpressure Handling

- Up to 4.5 bar

- Steam Consumption

- 1.2 - 4 kg/hr per 1000 LPH

- Cycle Time

- Adjusts automatically to flow

- Leakage Prevention

- Double sealing systems

- Float Rating

- High temperature float rated up to 200°C

- Condensate Outlet Temperature

- Up to 98°C

- Steam Inlet Size

- DN15/20

- Service Ports

- Multiple inspection and cleaning ports

- Minimum Water Level

- 50 mm above float

Steam Powered Condensate Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Steam Powered Condensate Pump

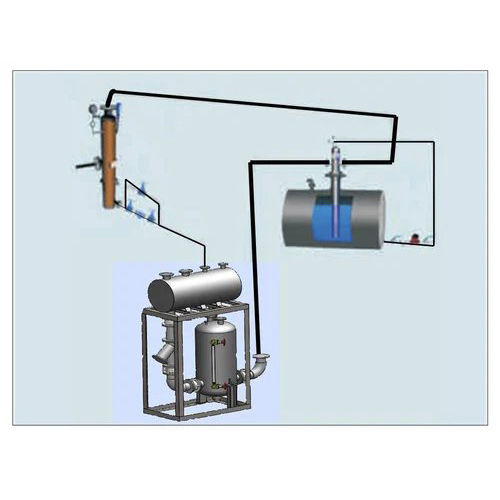

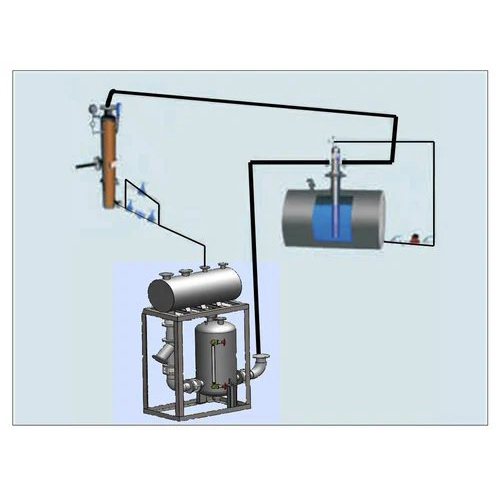

Introducing our Steam-Powered Condensate Pump, a game-changer in steam system efficiency. Harnessing the latent energy of steam, this pump excels at recovering and returning condensate to the boiler, preventing heat loss and optimizing overall system performance. Engineered for reliability and durability, it seamlessly integrates into steam setups, ensuring longevity in diverse industrial environments. The user-friendly design facilitates easy installation, making it a versatile solution for new and existing systems. By efficiently utilizing steam power for condensate management, this pump not only reduces operational costs but also champions sustainability, contributing to a greener industrial footprint. Upgrade your steam system with our innovative Steam-Powered Condensate Pump.

Specification

|

Model Name/Number |

IEPL 1 TO 12 TPH |

|

Brand |

IEPL |

|

Capacity |

1 TO 12 TPH |

|

Body Material |

MILD STEEL |

|

Color |

BLUE |

|

Material |

MILD STEEL |

Automatic, Maintenance-Free Operation

The built-in float control system automatically responds to flow conditions, optimizing cycling and eliminating the need for manual intervention. The double sealing system and service ports facilitate easy inspection and cleaning, ensuring consistent performance over years of usage without frequent maintenance.

Superior Corrosion Resistance and Safety

Featuring epoxy-coated internal surfaces, this pump resists aggressive steam and condensate environments. Integrated temperature and pressure relief valves enhance operational safety, safeguarding against overload situations and ensuring reliable operation under varying process conditions.

Versatility in Process Applications

Suitable for condensate recovery, boiler feed, and other steam-driven tasks, this pump seamlessly integrates into chemical, textile, and general process industries. With head sizes up to 8 meters, capacity up to 2500 LPH, and low noise emission, it offers remarkable adaptability on factory floors and skid-mounted installations.

FAQ's of Steam Powered Condensate Pump:

Q: How does the steam powered condensate pump operate without electricity?

A: The pump employs a reciprocating float mechanism actuated by steam pressure, which eliminates the need for any electrical components. Steam acts directly on the internal paddle and float, providing automatic, maintenance-free operation.Q: What is the benefit of the epoxy coated internal surfaces?

A: Epoxy coating protects internal components from corrosive steam and condensate, substantially extending the pump's service life and ensuring reliable performance, especially in industries handling aggressive fluids.Q: When should this pump be used in a process plant?

A: This condensate pump is ideal for applications requiring efficient recovery of hot condensate from steam systems, particularly in boiler feed systems and processes where electrical power is not available or suitable due to safety regulations.Q: Where can the pump be mounted in industrial settings?

A: The pump is designed for versatile installation and can be mounted on the floor or onto a skid. Its compact footprint and self-priming capabilities make it suitable for integration into various process layouts.Q: What maintenance and inspection options are available for this pump?

A: Multiple service ports allow convenient inspection and cleaning of internal components. With its maintenance-free float mechanism and double sealing system, the pump requires minimal routine maintenance compared to traditional pumps.Q: How does the pump handle varying flow rates and backpressure?

A: The adaptive cycling mechanism automatically adjusts the cycle time based on condensate flow. It can handle backpressure up to 4.5 bar and flow rates from 800 LPH up to 2500 LPH, accommodating fluctuations in condensate load.Q: What safety features are integrated in this condensate pump?

A: The pump is equipped with temperature and pressure relief valves, robust double sealing systems for leakage prevention, and is constructed to standards such as ASME and ISO 9001 for full compliance and operational safety.

Price 120000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Condensate Recovery System Category

Condensate Recovery System

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Mounting Type : Floor Mounted

Inlet/Outlet : 25 mm / 25 mm (BSP Threaded)

Noise Level : <70 dB

Capacity : As per design (standard 1002000 LPH)

Pressure Powered Pump

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Mounting Type : Horizontal

Inlet/Outlet : 2 inch / 2 inch

Noise Level : <70 dB

Capacity : 1025 m/h

Condensate Heat Recovery System

Price 160000 INR / Unit

Minimum Order Quantity : 1 Unit

Mounting Type : Floor Mounted

Inlet/Outlet : Flanged, Standard sizes as per requirement

Noise Level : Low Noise, <70 dB

Capacity : Customizable as per requirement

Pressure Powered Condensate Pump

Price 120000 INR / Unit

Minimum Order Quantity : 1 Unit

Mounting Type : Floor Mounted / Skid Mounted

Inlet/Outlet : DN25 to DN80, Flanged Connection

Noise Level : Below 70 dB (A)

Capacity : From 500 kg/h to 15,000 kg/h