Sonic Soot Blower

Sonic Soot Blower Specification

- Voltage

- 230 V Volt (v)

- Condition

- New

- Pressure

- Other

- Fuel Type

- Coal- Fired

- Output

- Steam

- Temperature

- 200 to 800 Planck temperature ()

- Style

- Horizontal

- Usage

- For Boiler tubes Cleaning Purpose

- Material

- SS

- Product Type

- Sonic Soot Blower

- Function

- for Cleaning purpose

- Color

- Silver

Sonic Soot Blower Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- AHMEDABAD

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 25 Pieces Per Month

- Delivery Time

- 30 Days

- Packaging Details

- Wooden Box

- Main Domestic Market

- All India

- Certifications

- Test Certificate

About Sonic Soot Blower

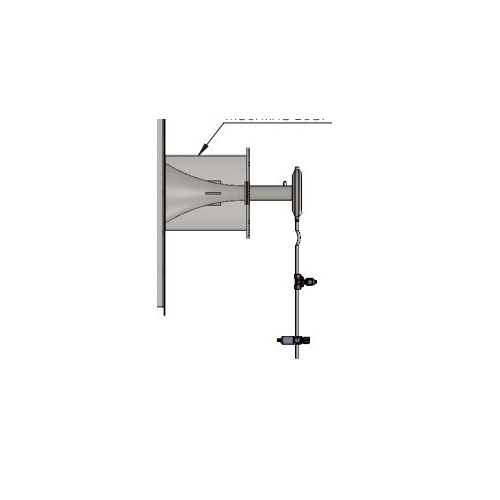

Introducing our Sonic Soot Blower a revolutionary solution for efficient boiler maintenance This cuttingedge device employs advanced sonic technology to dislodge and remove stubborn soot deposits from boiler surfaces Unlike traditional methods the Sonic Soot Blower operates without physical contact minimizing wear and tear while maximizing cleaning effectiveness Its precisely calibrated sonic waves penetrate and clean intricate boiler components ensuring peak thermal efficiency and prolonged equipment life Designed for versatility this blower adapts to various boiler types and sizes making it an indispensable tool for industries reliant on combustion systems Optimize your boilers performance with the Sonic Soot Blower a leap forward in industrial maintenance technology

IEPL Power Wave Acoustic Cleaning System is based on the principle of kinetic activation of the dust particles using sound waves generated by a sound generator operated by compressed air a microprocessorbased programmer controls the complete operation of system

IEPL Power Wave Acoustic Cleaning System is based on the principle of kinetic activation of the dust particles The sound generator sent out powerful sound signals of low frequency high intensity at suitable intervals inside the boilers or separators which cause the soot and other deposits to loosen and break away the bonds from the heated surfaces These loosen deposits may then drop down into the collection hoppers or be carries away with the flue gas It can save thermal energy when use in Boiler Fire tube path or save electrical energy when use in Bag filter

It applicable at Package Boilers Water tube boilers Waste heat recovery boiler Super heaters Economisers Air Heaters Gas Heat Exchanger Bag houses Electrostatic Precipitators fans Soils Hoppers Ductwork

Benefits

One time installation

Best to control pollution

Increased equipment service life

Lower operating cost

Low maintenance

Effective cleaning

Fully automatic operation

Continuous cleaning

Reduced the frequency of Boiler maintenance

Advanced Boiler Tube Cleaning

The Sonic Soot Blower offers a non-invasive cleaning solution for boiler tubes, leveraging sonic vibrations and high-temperature steam. This innovative approach minimizes manual intervention and downtime, maintaining energy efficiency in coal-fired boilers. Its durable stainless steel construction is engineered for rigorous use and longevity.

Efficiency and Safety Assured

By utilizing the Sonic Soot Blower, boiler operators can achieve maximum cleaning efficiency with enhanced safety. The devices operation at 230 V and high temperatures successfully removes soot residue, which can otherwise hinder heat transfer. This results in improved boiler performance and reduced fuel consumption over time.

FAQs of Sonic Soot Blower:

Q: How does the Sonic Soot Blower clean boiler tubes?

A: The Sonic Soot Blower uses controlled sonic vibrations combined with high-temperature steam output to dislodge and remove soot accumulation from the inner surfaces of boiler tubes without causing damage or requiring mechanical scraping.Q: What materials are used in the construction of the Sonic Soot Blower?

A: This device is primarily constructed from high-grade stainless steel (SS), ensuring resistance to corrosion and durability when exposed to high temperatures and steam within boiler environments.Q: When should the Sonic Soot Blower be used for boiler maintenance?

A: It is recommended to use the Sonic Soot Blower during scheduled boiler maintenance intervals or whenever there is a noticeable reduction in boiler efficiency due to soot buildup, to ensure consistent performance.Q: Where can I purchase or service a Sonic Soot Blower in India?

A: The Sonic Soot Blower is available through recognized exporters, manufacturers, suppliers, and service providers throughout India, catering to both industrial installations and maintenance requirements.Q: What is the process involved in operating the Sonic Soot Blower?

A: Operation involves positioning the blower horizontally along the boiler tubes and activating it at 230 V, where it emits steam at controlled temperatures between 200 and 800 Planck units while generating sonic vibrations to clear soot.Q: Why is the Sonic Soot Blower beneficial for coal-fired boilers?

A: Regular use of the Sonic Soot Blower in coal-fired boilers prevents soot accumulation, optimizes heat transfer, minimizes fuel consumption, and extends the lifespan of boiler tubes, contributing to cost-effectiveness and reliability.

Price 60000.00 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 25 Pieces Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Boiler Accessories Category

Rotary Airlock Valve

Price 50000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Fuel Type : Other

Function : Reduce Air

Condition : New

Pressure : Medium Pressure