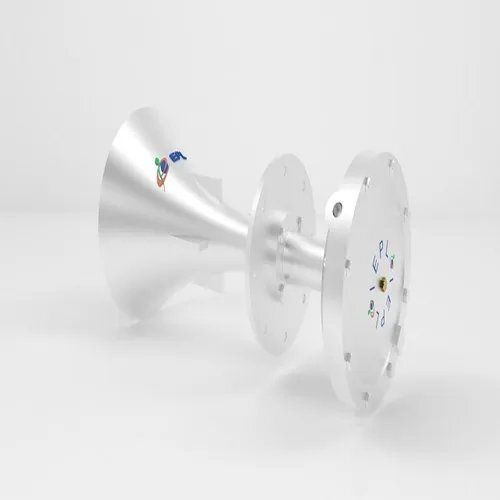

IEPL Best Acoustic Cleaning System

IEPL Best Acoustic Cleaning System Specification

- Material

- Mild Steel / Stainless Steel (as per requirement)

- Cavity

- Single / Multi Cavity Options

- Power

- 415 V, 3 Phase, 50 Hz

- Thickness

- Standard: 10 mm - 25 mm

- Application

- Industrial Dust Collectors, Precipitators, Boilers, Silos, Hoppers, Shells, Baghouses

- Temperature Range

- Up to 450C

- Dimension (L*W*H)

- Customizable as per requirement

- Density

- Gram per cubic centimeter(g/cm3)

- Fire Resistant

- Yes

- Maintenance

- Low; Periodic inspection recommended

- Shape

- Cylindrical or As specified

- Service Life

- Designed for continuous operation

- Compliance

- Meets industrial safety and environmental standards

- Acoustic Frequency

- 350 Hz450 Hz

- Ingress Protection

- IP-65 (for controller housing)

- Installation Location

- External or Internal (on suited vessels/equipment)

- Vibration Generation Method

- High Impact Acoustic Pulse

- Operating Pressure

- 3 to 7 Bar (Compressed Air) (if pneumatic option included)

- Color/Finish

- Industrial Epoxy coated / Painted

- Mounting Type

- Flanged or Welded

- Sound Pressure Level

- 145 dB to 155 dB

- Control System

- Microprocessor based automatic controller

IEPL Best Acoustic Cleaning System Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About IEPL Best Acoustic Cleaning System

Versatile Application Surfaces and Media

The IEPL Best Acoustic Cleaning System is adaptable for both internal and external applications, explicitly designed for industrial dust collectors, boilers, precipitators, silos, hoppers, bags, and shells. With surface options tailored as per vessel or equipment requirements, its robust construction allows usage across a wide spectrum of application media, including fine powders, dust, and residues. Used as a non-contact, high-impact cleaning solution, it ensures safe, effective residue removal while maintaining structural integrity.

Secure Supply, Prompt Delivery, and Trusted Valuation

IEPL ensures that every Acoustic Cleaning System is valued for its engineering excellence and delivered with swift transport services. Each order is carefully packaged for secure international shipping, with customizable delivery times to suit project needs across India and globally. Supply ability is robust-large volumes dispatched reliably with transparent valuation, ensuring clients receive the right specification on time. Our packaging safeguards your investment, maintaining product integrity during transport.

FAQ's of IEPL Best Acoustic Cleaning System:

Q: How does the IEPL Acoustic Cleaning System function in industrial applications?

A: The system generates high-impact acoustic pulses in the 350-450 Hz frequency range, breaking up dust and residue deposits without causing physical wear or damage to equipment-ideal for use in dust collectors, boilers, precipitators, and silos.Q: What materials and finishes are available for customization?

A: Customers can choose between mild steel or stainless steel construction, with options for industrial epoxy coating or painting. Dimensions, cavity design, and shapes are customizable to fit specific equipment requirements.Q: When is periodic inspection recommended for maintenance?

A: Although the system is designed for continuous operation with low maintenance, periodic inspections are recommended to ensure optimal performance and longevity, in alignment with standard industrial practices.Q: Where can the acoustic cleaning system be installed?

A: It's suitable for both internal and external installation on various vessels, equipment, and structures across industries, offering flexibility for dust remediation projects of all scales.Q: What are the main benefits of using this system?

A: Key benefits include reduced maintenance downtime, improved cleaning effectiveness, compliance with safety and environmental standards, and suitability for high-temperature and hazardous environments (up to 450C).Q: How do I redeem discounts or access the price cut on this system?

A: Simply Add to Cart through authorized channels or contact our sales team to redeem the latest price cut offers. Our team will guide you through the procurement process, including any customizations needed.

Price 60000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Acoustic Horns Category

Acoustic Cleaners

Price 75000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Material Dislodging, Silo/Hopper Cleaning, Buildup Removal

Cavity : Single / Multiple

Fire Resistant : Yes

Dimension (L*W*H) : Customizable

Power Wave Acoustic Cleaning System

Price 69500 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Boiler, Silos, ESP, Heat Exchangers, Filters, Bins

Cavity : Single and MultiCavity options

Fire Resistant : Yes

Dimension (L*W*H) : 300 mm x 450 mm x 120 mm

Boiler Acoustic Horn

Price 68000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Boiler soot blowing, preventing ash buildup

Cavity : Single chamber

Fire Resistant : Yes

Dimension (L*W*H) : 450mm x 320mm x 170mm

Acoustic Horns

Price 73000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Industrial warning, Public Alarm, Marine and Mining Industries

Cavity : Single

Fire Resistant : Yes

Dimension (L*W*H) : 600 x 400 x 300 mm