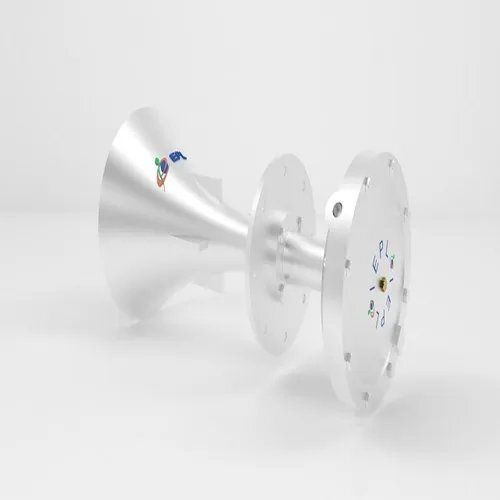

Acoustic Horn For Boiler

Acoustic Horn For Boiler Specification

- Material

- Stainless Steel / Carbon Steel

- Cavity

- Single/Multiple, tailored as required

- Power

- 230/415 V AC, 50 Hz

- Thickness

- Varies as per Model

- Application

- Soot Cleaning in Boilers, Heat Exchangers, and Heaters

- Temperature Range

- Up to 550C

- Dimension (L*W*H)

- Custom as per Boiler Design

- Fire Resistant

- Yes

- Weight

- Depends on Model, typically 10-30 kg

- Mounting

- Flange / Direct on Boiler Drum

- Control

- PLC / Timer Based

- Sound Pressure Level

- 130-145 dB

- Corrosion Resistance

- Excellent (Anti-corrosive Coating)

- Blowing Cycle

- Programmable, 15-60 sec per cycle

- Operating Medium

- Compressed Air or Steam

Acoustic Horn For Boiler Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

About Acoustic Horn For Boiler

Technical Brilliance: Acoustic Horn Features & Usage

The Acoustic Horn for Boiler showcases advanced features, including PLC/timer-based control, programmable blowing cycles, and robust fire and corrosion-resistant construction. It's suitable for general and specific use in soot cleaning, especially in boilers, heat exchangers, and process heaters. Designed for heavy-duty industrial applications, it offers custom configurations in terms of size, material, and cavity options. Its ease of use and reliability make it an essential asset for maintaining plant efficiency.

Sample Policy & Certifications: Seamless Supply and Delivery

We offer sample requests at a reasonable asking price, ensuring customers can evaluate the Acoustic Horn's superiority firsthand. Packaging is expertly handled to guarantee safe transit and delivery worldwide. Shipped securely, our product adheres to international industrial standards and comes with all necessary certifications. We supply throughout India and export globally, supporting our commitment to both quality and prompt dispatch.

FAQ's of Acoustic Horn For Boiler:

Q: How does the Acoustic Horn improve boiler cleaning efficiency?

A: The Acoustic Horn delivers powerful sound waves (130-145 dB) that dislodge soot and ash from internal boiler surfaces, improving heat transfer and system performance, while reducing manual cleaning frequency.Q: What is the recommended process for installing the Acoustic Horn?

A: Installation is straightforward, requiring flange or direct mounting on the boiler drum. The device should be integrated with the boiler's PLC or timer for automated control, following the provided mounting and wiring instructions.Q: When should I use the programmable blowing cycle function?

A: Use the programmable blowing cycle (15-60 seconds per cycle) to schedule regular cleaning intervals, minimizing deposit build-up and ensuring consistent boiler operation without interrupting processes.Q: Where can the Acoustic Horn be effectively used?

A: Apart from boilers, it can be deployed in heat exchangers and process heaters, making it versatile for a range of industrial applications needing soot or ash removal.Q: What are the main benefits of the anti-corrosive and fire-resistant design?

A: The corrosion-resistant coating and fire-resistant materials ensure a long operational life, even in harsh, high-temperature industrial environments, reducing maintenance and replacement costs.Q: How is the Acoustic Horn powered and controlled?

A: The horn operates on 230/415 V AC, 50 Hz, and is controlled via PLC or timer systems, allowing for easy integration into automated plant operations.

Price 72000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Acoustic Horns Category

Power Wave Acoustic Cleaning System

Price 69500 INR / Unit

Minimum Order Quantity : 1 Unit

Cavity : Single and MultiCavity options

Dimension (L*W*H) : 300 mm x 450 mm x 120 mm

Power : 220 V / 50 Hz

Temperature Range : Up to 1100C

Acoustic Cleaners

Price 75000 INR / Unit

Minimum Order Quantity : 1 Unit

Cavity : Single / Multiple

Dimension (L*W*H) : Customizable

Power : 230 V AC / 24 V DC

Temperature Range : 20C to +450C

Boiler Acoustic Horn

Price 68000 INR / Unit

Minimum Order Quantity : 1 Unit

Cavity : Single chamber

Dimension (L*W*H) : 450mm x 320mm x 170mm

Power : 230V AC / 24V DC

Temperature Range : Up to 1100C

Acoustic Horns

Price 73000 INR / Unit

Minimum Order Quantity : 1 Unit

Cavity : Single

Dimension (L*W*H) : 600 x 400 x 300 mm

Power : Mechanical, No Power Required

Temperature Range : 10C to 60C